FeatureRECOGNITION is a powerful way to simplify and accelerate programming. By programming parts based on features in the CAD model, FeatureCAM streamlines machining and makes it easier to create and edit parts.

The knowledge-based technology in FeatureCAM gives you a powerful CAM system that combines automation with control. FeatureCAM generates toolpaths based on the features of the part and then automatically selects appropriate tools, determines roughing and finishing passes, and calculates feeds and speeds based on the software’s built-in machining knowledge.

Ease of use is a guiding principal in the development of FeatureCAM. Graphical feedback, step-by-step wizards and tutorial-style animations run directly in the program dialog boxes. Ease of use has always been a FeatureCAM advantage and with feedback from our customers we continue to study ways to make the software even easier to learn and use.

FeatureCAM offers a comprehensive solution for milling, turning, turn/mill and wire EDM. All of your machine tools can be programmed within a single user interface designed to shorten programming times and reduce the learning curve for new users. Integrated 3D machine simulation, together with a library of over 350 fully customisable post-processors, lets you visualise exactly how your parts will be machined.

Based on more than 20 years of development, FeatureCAM generates quality toolpaths – allowing you to produce parts of the highest standard for your customers. Delcam’s policy of code sharing between its CAM software solutions has resulted in FeatureCAM benefiting from many of PowerMILL’s proven strategies for high-speed machining and 5-axis machining. Multi-threading, the process of splitting toolpath calculation across multiple CPUs, lets you program your parts faster than ever before.

THE CUSTOMERS WORDS

I recommend FeatureCAM because it’s really easy to learn and you can start making your parts right away.

I can go from a concept to a finished part in one afternoon now, where as it used to take me several days.

It’s really reduced our programming time to minutes instead of hours.

I like FeatureCAM because it’s so easy to use.

For more information on purchasing feel free to contact us at Lone Star Fabrication or follow the button to contact FeatureCAM direct.

Do you need to deliver products to clients under increasing time constraints and want the ability to develop products faster and more efficiently, sharing common data across a single integrated product suite?

Do you need to make unanticipated product changes from customer feedback and want the ability to change models at any stage in the design process, free from the burden of constraints and feature dependencies, and to automatically update all related documentation?

Do you need to communicate product designs and want the ability to share information and involve customers, supply chain and the extended global team in your design process?

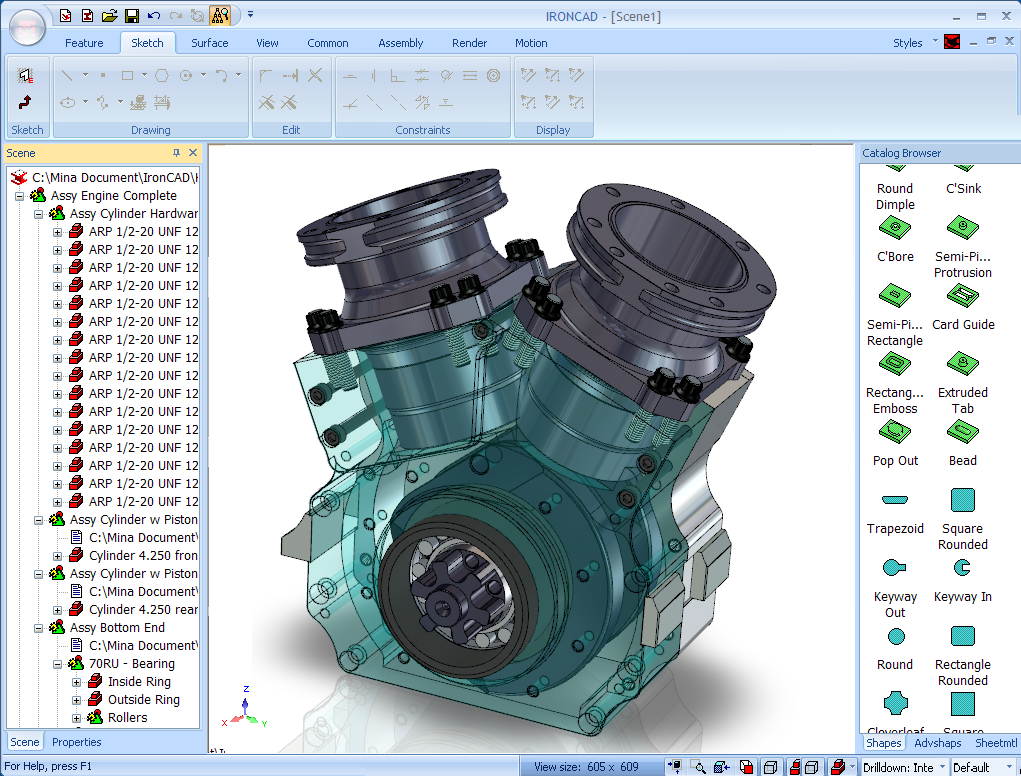

DRAG AND DROP

- Only system in the industry making design simple and easy to construct and reuse geometry.

INTELLISHAPES

- Intuitive objects with handles for sizing and intelligence to make common tasks predefined.

UNIFIED DESIGN ENVIRONMENT

- Create parts and assemblies in a single file simplifying file management and reducing design time.

TRIBALL

- Powerful tool to position and orient your component in any orientation with ease.

THE CUSTOMERS WORDS

Increased our productivity by 50%

Assembly layout is significantly faster with IronCAD

75% more productive than SolidWorks

Design largescale projects in a single file

A 15 year old can learn IronCAD in 2 days!

More things just get done in less time, period!

For more information on purchasing feel free to contact us at Lone Star Fabrication or follow the button to contact IronCAD direct.